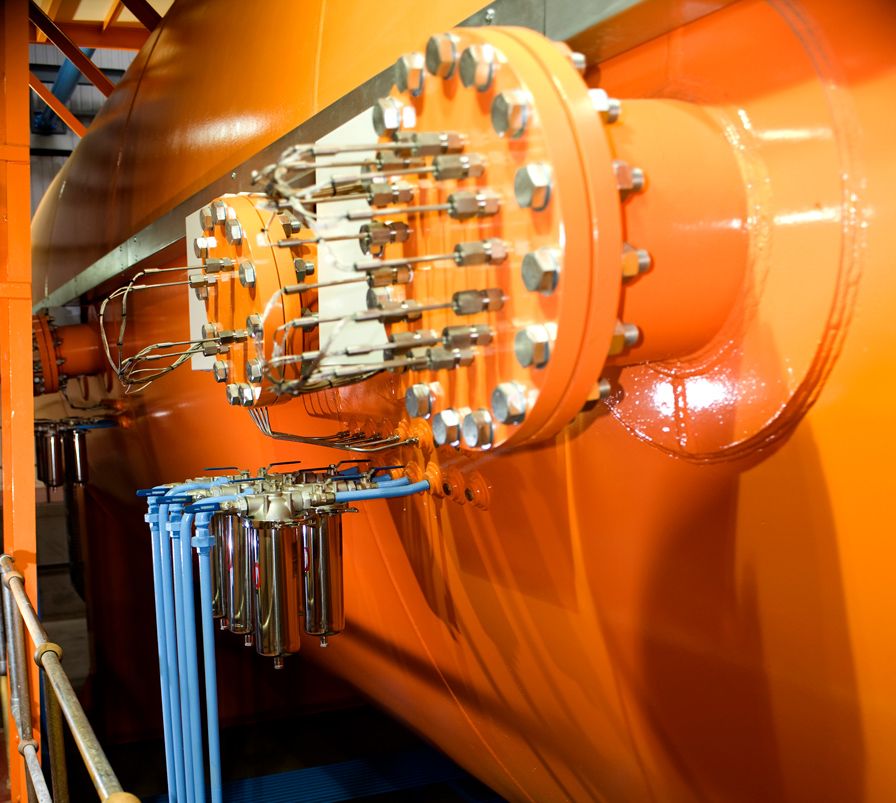

Premier Autoclaves: Industry-Leading Autoclave Solutions with Unmatched Service & Support

At Premier Autoclaves, we’re proud to be a world-class provider of advanced autoclave systems, specialising in carbon fibre curing, composite autoclaves, and high-pressure autoclave solutions. With decades of industry experience across our team, we’ve built our reputation not only on manufacturing and supplying top-tier autoclaves but also on delivering unmatched, ongoing service and support to our clients. From Formula 1 to aerospace, automotive, space and defence, we’re deeply embedded in industries that require the most precise composite curing and advanced materials processing. Whether you need a small autoclave for prototyping or a large autoclave for high-volume production, Premier Autoclaves ensures reliable performance with a robust service foundation that lasts throughout the lifecycle of your equipment.

At the heart of our business is a commitment to exceptional customer support that goes far beyond your initial purchase. We’re experts in both autoclave technology and the industries we serve, offering tailored solutions for the demanding criteria of the sectors we work in. As trusted partner to the world’s best manufacturers, we provide planned support to ensure your autoclaves remains at peak performance, year after year. Whether you’re an aerospace prime or an innovative automotive start-up, you can rely on Premier Autoclaves for not just industry-leading solutions but also the ongoing service that ensures your success long after installation.

We take care of your autoclave. So you can take care of business.

“We chose Premier for their deep industry understanding and commitment to developing solutions for demanding performance criteria.”

“At 4pm your engineer was looking for ways to solve the problem, rather than reasons to head home.”

“Potential issues are diagnosed before they happen”

“Following the benefits seen with our first upgrade, we have upgraded two more autoclaves with Premier”

“There is a genuine desire at every level to do the very best for their customers.”

Autoclave Services

New Autoclaves

Best in class brand new autoclaves trusted in F1, aerospace, defence, automotive, space and all advanced material curing.

Autoclave Servicing

The foundation of our business. Our customers don’t have spare autoclaves so our ongoing support is critical.

Autoclave Upgrades

Automate production, transform productivity, enhance traceability, attract new business.

Critical Spares

In combination with periodic servicing reduces downtime, cost to the business, and ensure reliable performance.

Contact Premier Autoclaves

Trusted by the world’s best advanced material manufacturers to…

- Increase Productivity

- Assure Quality Standards

- Reduce Production Costs

Autoclave Upgrades

Maximise Your Autoclave's Potential with Expert Upgrades

At Premier Autoclaves, we specialise in upgrading autoclaves to enhance performance, safety, and efficiency across industries like aerospace, automotive, defence, and more. Our upgrades improve production efficiency by up to 300% through automated processes, streamline operations, and ensure compliance with safety standards such as PM73 HSE.

We also help reduce energy consumption with inverter-driven motors, improve system reliability with upgraded parts, and enhance production quality by optimising vacuum and thermocouple systems. By upgrading rather than replacing your autoclave, you can achieve cost savings while extending the life of your equipment.

Our tailored solutions integrate autoclaves with ERP systems, improving workflow and boosting productivity. Additionally, we offer upgrades that contribute to sustainability goals, such as ISO 14001 certification.

Autoclave FAQs

How does the autoclave manufacturing process work?

The autoclave is essentially a three-dimensional press or pressurised oven. Closely defined levels of pressure and heat are applied within a chamber to cook or ‘cure’ advanced material components such as F1 nose cone or an aeroplane wing. Pre-impregnated composite material or ‘prepreg’ starts is used as a light and strong alternative to metal in numerous advanced engineering sectors, with the process for curing as follows.

- Lay-up of Composite Materials

The first step involves laying up composite materials, such as carbon fibre. The material is often pre-impregnated with a resin system (prepregs), and these layers are placed over a mould in specific orientations to achieve the desired strength and stiffness.

- Vacuum Bagging

Once the lay-up is complete, the materials and mould are covered with a sealed vacuum bag. When the vacuum is applied inside the bag, trapped air is removed so resin can bond equally throughout the fibres.

- Autoclave Curing

The sealed mould is placed inside the autoclave- a large, pressurised oven that applies heat and pressure to the composite material. The heat catalyses the curing of the resin, and the pressure helps compress the material, which supports bonding between the layers.

- Temperature and Pressure Ramp-Up

The autoclave’s temperature and pressure gradually increase according to component and material-specific recipes. This controlled increase prevents the development of internal stresses within the material.

- Holding Phase

Once the target temperature and pressure are reached, these conditions are maintained for a given time. This holding phase allows the resin to fully cure and cross-link, forming a solid, durable matrix within the composite. There may be multiple ramps and holds / dwells.

- Cooling Phase

After the holding time, depending on capabilities and requirements the autoclave can be gradually cooled to ambiant while maintaining pressure to avoid warping or deforming the material.

- Pressure Release and Unbagging

When the autoclave reaches room temperature, the pressure is carefully released. The vacuum bag is removed, and the composite part is extracted from the mould.

- Post-Curing and Machining

Some composites may require a post-curing step outside the autoclave to achieve their final properties. Machining or other finishing processes are also applied to meet certain specifications.

- Inspection and Quality Control

The final step involves thoroughly inspecting the composite part to ensure it meets design and quality specifications. Techniques such as ultrasonic testing, X-ray, or visual inspections are commonly used.

Pressure in a Composite Autoclave

The pressure in an autoclave typically around 100psi, but can range from 70 to 300psi, which is 5 to 20 times atmospheric pressure.

Temperature of Composite Autoclave

For materials such as carbon fibre-reinforced plastics (CFRPs), the temperature in an autoclave is typically maintained between 120°C and 180°C. This activates the resin’s chemical hardeners and solidifies the matrix around reinforcing fibres. However, other materials, such as thermoplastic CFRP (CFRTP), may need processing temperatures up to 390°C. Fluctuations in temperature can lead to incomplete curing or defects, such as resin-rich or resin-poor areas, which may weaken the composite. Therefore, the temperature must be controlled carefully with advanced sensors and automated control systems such as Premier’s Prodigy system.

Autoclave for Aerospace and Automotive

Autoclaves are used to manufacture aerospace and automotive components. Applying controlled heat and pressure allows manufacturers to produce incredibly strong, lightweight components such as aircraft fuselage panels and automotive chassis parts. This improves fuel efficiency, reduces emissions and enables more aerodynamic designs.

Conclusion – Autoclave for Composite Curing

Autoclave curing is an effective manufacturing method that combines heat and a pressurised stream to produce lightweight, strong composite materials. It catalyses the curing of the resin, compresses the material, and supports bonding between the layers. Temperature and pressure settings vary depending on the type of material being used and the required outcome.

Thank you to our customer Piran Composites for the content here- take a look at their website (add link) for some of the brilliant things they are doing…

What is a composite material?

A composite material is a type of material that is created by combining two or more constituent materials with dissimilar chemical or physical properties. In combining these two materials, the resulting composite material will have new properties superior to the original components.

Unlike traditional materials, where the substances are blended or dissolved together, in composites, the individual materials retain their separate identities. One substance, called the matrix, acts as a binder, holding the other substances, called reinforcements or fibres, in place. This unique composition allows composites to possess a combination of properties from the different materials, resulting in enhanced strength, durability, or other desirable characteristics.

Thank you to our customer Piran Composites for the content here- take a look at their website (add link) for some of the brilliant things they are doing…

What is a pre-preg?

A pre-preg (short for pre-impregnated composite material) is a composite material that consists of reinforcing fibers (such as carbon fiber, fiberglass, or aramid) that are already impregnated with a resin (typically an epoxy resin or thermoset resin) before being used in the manufacturing process. The resin is only partially cured, which means it is still flexible and can be easily molded or shaped into the desired form.

Key Features of Pre-Preg:

- Controlled Resin Content: The resin content is carefully controlled to ensure optimal performance.

- Partially Cured: Pre-preg is partially cured (also called “B-staged”), meaning it’s not fully hardened. This allows the material to be worked with, shaped, and stored before final curing.

- Storage: Because pre-preg material is partially cured, it needs to be stored in cold conditions (usually in a freezer) to prevent it from fully curing before use.

- High-Quality and Consistent Performance: Pre-preg allows for consistent resin-to-fiber ratios, resulting in higher-quality finished products with superior mechanical properties.

Applications:

- Aerospace: Used for making high-performance parts like aircraft wings, fuselages, and other critical components that need to be both strong and lightweight.

- Automotive: Common in motorsport (like Formula 1) and high-performance automotive parts.

- Marine: Used for boat hulls and other high-strength components.

- Sports Equipment: In items like bicycles, tennis rackets, and skis.

- Medical Devices: In structural components of medical devices where strength and precision are essential.

Pre-preg is popular for producing high-performance composite parts because of its ability to ensure precise fiber alignment and consistent resin distribution, which improves the overall strength, durability, and lightweight characteristics of the finished component. After the material is molded into the desired shape, it is typically fully cured in an autoclave under heat and pressure to harden the resin and finalize the part’s properties.

Do you support glass autoclaves?

Yes. While not our core market, we have numerous glass customers as our expertise is not only transferrable but of benefit. Advanced material cure monitoring and traceability common in composites has been helpful to some glass customers in reducing the need for re-bakes or eliminating bubbles in certain laminates. After upgrading control systems, customers have better understood cures, enhanced efficiency and improved quality of products.

Do you support sterilising autoclaves?

Quite an easy one- desktop sterilisation machines are not our game and we do not support them. We’d recommend speaking to contact@certusbiomed.com