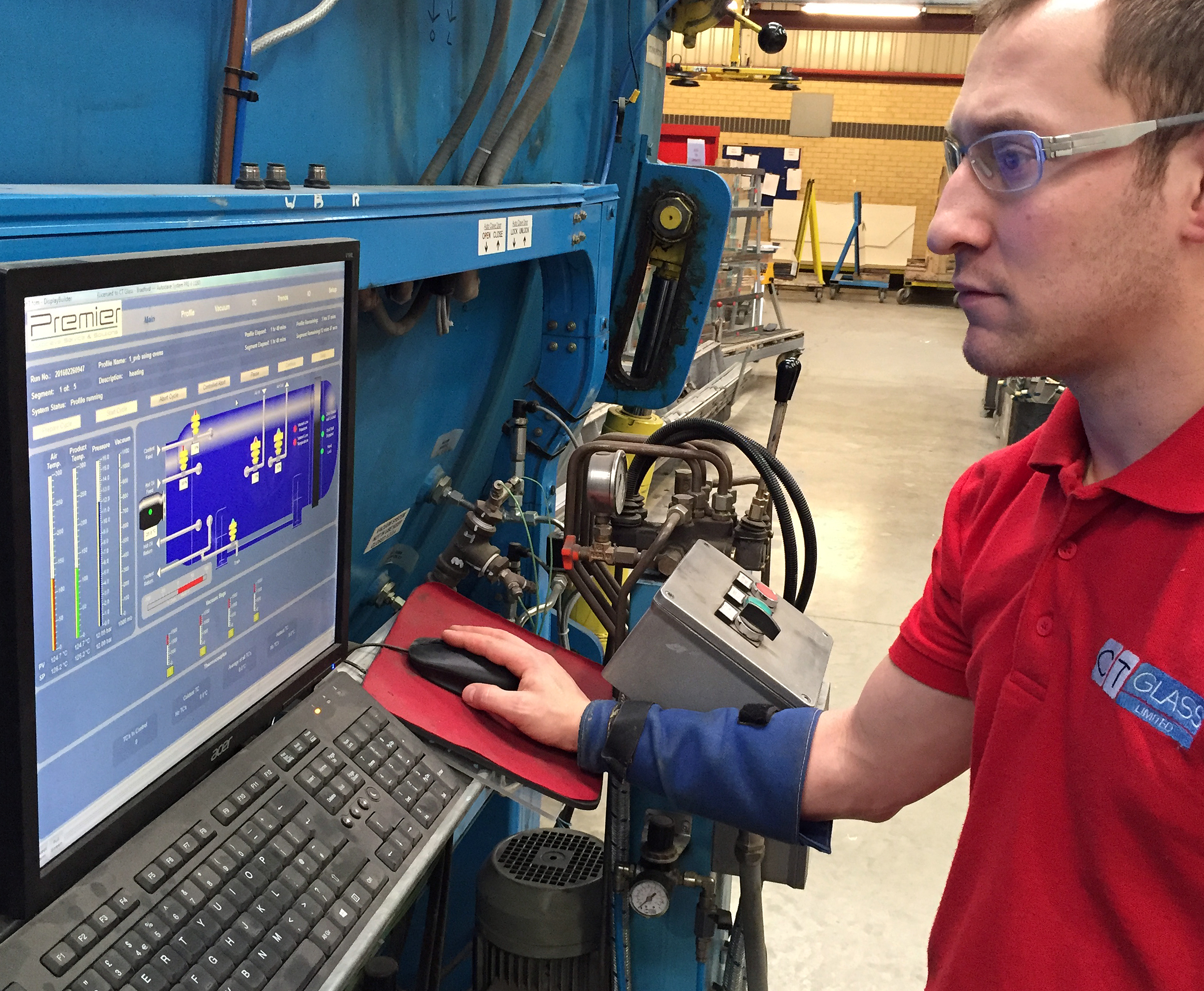

Premier has recently completed a controls and hardware upgrade for CT Glass which has modernised the controls and implemented complete traceability and given a greater understanding of the cures which they use.

Premier has recently completed a controls and hardware upgrade for CT Glass which has modernised the controls and implemented complete traceability and given a greater understanding of the cures which they use.

Chris Barley, Supervisor at CT Glass said, “Our operators all agree the system is very user friendly: within a few clicks we can pull off all required data. I also found it useful that the software can be customised to our needs. In terms of support, every time I contact Premier staff they are extremely helpful and reaction time is immediate- very important for us.”

Reason for works:

Modernise controls to increase efficiency, implement complete traceability & improve understanding of cures.

Description of works:

- Upgraded front end controls to Premier’s specifically designed CureManager software.

- Safety system upgraded to comply with PM73 HSE guidelines, bag-burst protection system installed, thermocouples transition (independent of controls) added for thermal uniformity surveys.

- Minimised customer disruption: Premier undertook most of works offsite and installed through 2 consecutive weekends and only 5 working days (including training and commissioning).

Benefit to customer:

- Greater understanding of autoclave thermal dynamics (using new thermal uniformity thermocouples) have improved production efficiency.

- 24/7 in-depth traceability enables detailed assessment if parts quality requires attention.

- Bag-burst protection system isolates automatically in the event of a leak, protecting other bags from positive pressure ingress.

- Supportable, reliable components installed ensuring minimised downtime in the event of a breakdown.